AI Automation in Electronics Manufacturing: Future Insights

How AI-Enabled Automation Is Shaping Smart Electronics Manufacturing

The electronics manufacturing industry is evolving rapidly, driven by increasing product complexity, shorter life cycles, and rising quality expectations from OEMs and Tier-1 customers. To meet these demands, manufacturers are moving beyond conventional automation and adopting AI-enabled, data-driven manufacturing practices within smart factory environments.

AI automation in electronics manufacturing is not about replacing human expertise – it is about enhancing manufacturing execution, improving process stability, ensuring consistent quality, and enabling economical operations across high-mix and recurring production programmes.

The Shift Towards Smart Manufacturing in Electronics

Smart manufacturing combines automation, data analytics, and connected systems to create highly efficient and responsive production environments. In electronics manufacturing, this approach supports:

- Better process visibility across PCBA, wiring harness, and box-build assembly

- Improved control over quality and traceability

- Faster response to demand changes and engineering updates

By integrating AI-assisted tools into manufacturing operations, smart factories enable real-time monitoring, informed decision-making, and continuous process improvement – all critical for today’s electronics supply chains.

Role of AI in Electronics Manufacturing Operations

AI plays a growing role in strengthening core manufacturing processes rather than acting as a standalone technology. When embedded into electronics manufacturing operations, AI supports:

Predictive Maintenance and Equipment Reliability

AI systems analyse machine data from SMT lines, testing equipment, and assembly stations to identify performance trends and early warning signs. This enables planned maintenance, reduces unplanned downtime, and improves overall equipment effectiveness – critical for meeting delivery commitments.

AI-Assisted Quality Control

In electronics manufacturing, quality consistency is non-negotiable. AI-enabled inspection systems enhance traditional AOI and testing by identifying defect patterns, process drifts, and repeat issues that may not be visible through manual inspection alone.

This supports lower rework, reduced scrap, and improved first-pass yield across PCBA and electromechanical assemblies.

Data-Driven Process Optimisation

AI-supported analytics help manufacturers study production data across builds, identify bottlenecks, and improve process parameters. This is especially valuable in high-mix, low-volume manufacturing, where stability across multiple part numbers is essential.

Intelligent Manufacturing Systems in Smart Factories

Smart factories rely on a combination of interconnected technologies working together:

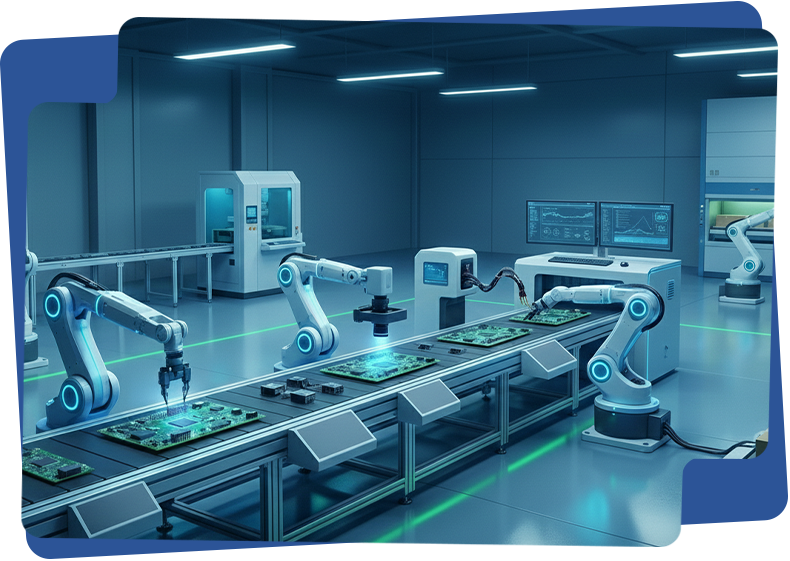

Automation and Robotics

Automation supports precision, repeatability, and productivity in electronics manufacturing. Robotic systems assist in assembly, material handling, and repetitive operations, improving throughput while maintaining consistent quality standards.

IoT and Connected Manufacturing

IoT-enabled machines and sensors provide real-time production data, enabling better monitoring of equipment health, process conditions, and output quality. This connectivity strengthens traceability and supports proactive decision-making on the shop floor.

Data Analytics and Machine Learning

By analysing manufacturing data across time, machine learning models help manufacturers understand defect trends, improve process control, and implement corrective actions faster. This data-centric approach drives continuous improvement and long-term manufacturing stability.

Benefits of AI-Enabled Automation in Manufacturing

When applied practically within electronics manufacturing operations, AI-enabled automation delivers measurable benefits:

- Improved Efficiency: Faster cycle times, better equipment utilisation, and reduced downtime

- Consistent Quality: Enhanced inspection, early defect detection, and stable processes

- Economical Operations: Optimised resource usage, lower rework, and reduced waste

- Enhanced Safety: Reduced manual intervention in repetitive or high-risk tasks

These benefits directly support OEM expectations for quality, reliability, and scalable production.

Challenges to Consider

While AI-enabled manufacturing brings clear advantages, successful implementation requires careful planning:

- Initial Investment: Automation and digital systems require upfront investment aligned with long-term production goals

- Skill Development: Workforce training is essential to operate and manage advanced manufacturing technologies

- Data Security: Increased connectivity demands strong cybersecurity practices to protect sensitive manufacturing data

Manufacturers that approach AI adoption with a practical, process-focused mindset achieve the best long-term outcomes.

inYantra Technologies: Advancing Smart Electronics Manufacturing

inYantra Technologies Pvt Ltd integrates AI-enabled automation and data-driven manufacturing practices within its electronics manufacturing operations to support OEMs and global customers.

With capabilities across:

- PCBA (SMD, THT, BGA, Flex, Hybrid)

- Wiring harness and electromechanical assembly

- Box-build and system integration

- Advanced inspection and testing

inYantra leverages intelligent manufacturing practices to improve quality consistency, process control, and delivery reliability. AI-assisted inspection, predictive equipment monitoring, and data-driven process optimisation support high-mix and recurring production requirements across industries.

Backed by globally recognised certifications and strong manufacturing discipline, inYantra focuses on building and assembling electronics products with reliability, traceability, and long-term partnership in mind.

Conclusion: The Future of Electronics Manufacturing

AI-enabled automation and smart factory practices are becoming essential in modern electronics manufacturing. Manufacturers who embed intelligence into their production processes – rather than treating AI as a standalone solution – are better positioned to deliver quality, flexibility, and operational stability.

For OEMs seeking dependable manufacturing partners, the future lies in collaboration with organisations that combine strong manufacturing fundamentals with smart, data-driven execution.

By continuously enhancing its manufacturing operations through intelligent automation, inYantra Technologies supports customers in navigating the evolving electronics manufacturing landscape with confidence.