How IoT is Changing Electronics Manufacturing in 2025

The landscape of electronics manufacturing is undergoing a profound transformation, driven by the power of the Internet of Things (IoT). As we move into 2025, IoT continues to expand its influence—bringing new levels of efficiency, connectivity, and innovation.

This article explores how IoT is reshaping electronics manufacturing and how inYantra Technologies Pvt. Ltd. is embracing these advancements to align with the Industry 4.0 revolution.

Understanding IoT in Electronics Manufacturing

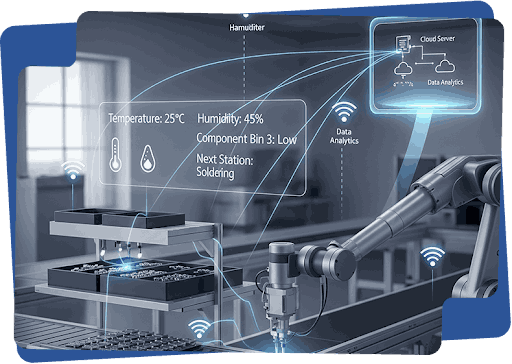

IoT refers to the network of interconnected devices that exchange data in real-time. In manufacturing, IoT creates smart ecosystems where machines, systems, and products work seamlessly together. This integration enables real-time monitoring, smarter analytics, and automated workflows.

At inYantra Technologies, IoT-driven insights are being adopted to strengthen operations, enhance predictive quality checks, and support customers with faster, more reliable deliveries.

The Role of Industry 4.0

Industry 4.0, also known as the Fourth Industrial Revolution, integrates IoT, artificial intelligence (AI), and data analytics into modern production. For electronics manufacturing, it means building adaptive, efficient, and responsive factories that deliver consistent quality and faster time-to-market.

Key Benefits of IoT in Electronics Manufacturing

Enhanced Operational Efficiency

IoT solutions help monitor production in real time, identify bottlenecks, reduce downtime, and optimize resource utilization. By leveraging data insights, manufacturers can make faster and smarter decisions—boosting overall productivity.

Predictive Maintenance

Using IoT sensors, manufacturers can predict potential equipment failures and schedule proactive maintenance. This minimizes downtime, extends machine life, and lowers repair costs.

Quality Control and Assurance

IoT-enabled quality checks ensure that every stage of production is monitored in real time. This reduces defects, avoids costly recalls, and helps maintain uncompromised standards.

IoT Solutions Transforming Electronics Manufacturing

Smart Manufacturing Systems

Smart manufacturing systems integrate IoT devices and analytics to create connected, automated production. For manufacturers like inYantra, this translates into greater flexibility and responsiveness in serving diverse industries.

Digital Twins

Globally, digital twins—virtual replicas of processes or equipment—are becoming critical for optimizing design and production. At inYantra, these emerging technologies are being closely tracked as part of its Industry 4.0 journey, with the goal of future integration into smart operations.

Strategic Logistics & Delivery

While inYantra focuses on electronics manufacturing, its location near highways and ports ensures reliable, cost-efficient delivery. By aligning with IoT-enabled logistics and tracking systems, inYantra continues to strengthen its ability to serve both domestic and export markets.

Challenges and Considerations

Data Security and Privacy

The growth of IoT also introduces cybersecurity risks. Protecting data integrity and preventing breaches is essential as IoT adoption increases.

Integration and Interoperability

Blending IoT technologies with legacy equipment can be challenging. Standardization and compatibility will be critical for smooth adoption across the industry.

The Future of IoT in Electronics Manufacturing

AI-Powered IoT

By combining AI with IoT, manufacturers can move toward predictive analytics, autonomous decision-making, and self-optimizing production. While still emerging, these advancements signal the next phase of Industry 4.0.

Sustainable Manufacturing Practices

IoT plays an important role in sustainability by reducing energy consumption, minimizing waste, and optimizing resource usage—helping manufacturers meet environmental goals.

Conclusion

In 2025, IoT is reshaping electronics manufacturing with smarter factories, predictive systems, and data-driven processes.At inYantra Technologies, IoT insights are already being adopted to enhance efficiency, strengthen quality, and enable strategic delivery. By aligning with Industry 4.0 trends, inYantra is preparing customers for the future of smart, connected manufacturing—delivering uncompromised quality, faster turnaround, and long-term reliability.