Why PCB Assembly Quality Defines Your Product’s Reliability

In the world of electronics, every product – from industrial controllers to EV chargers – depends on the heart of its design: the Printed Circuit Board (PCB). The performance, longevity, and safety of your product are only as strong as the quality of its PCB assembly.

At inYantra Technologies, we understand that PCB assembly quality is not just a manufacturing step – it’s the foundation of reliability and brand trust.

1. Precision in SMT Assembly: The Core of Every Reliable Product

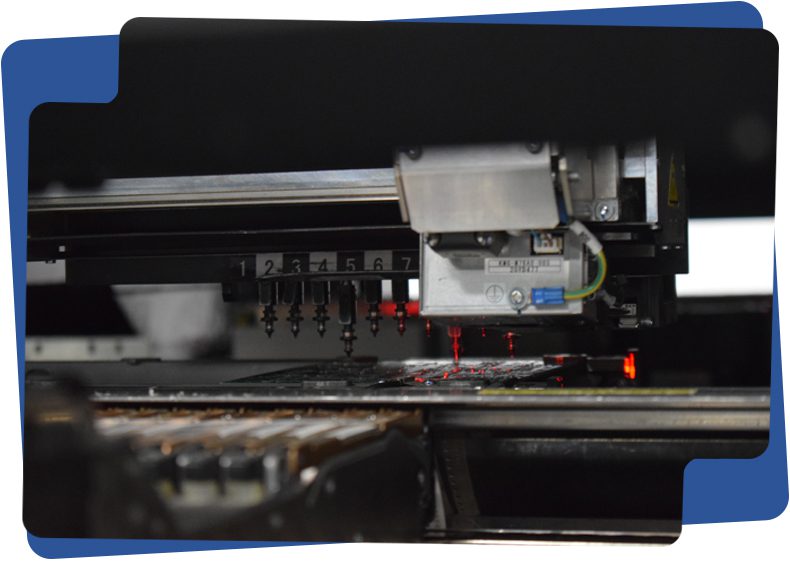

Surface Mount Technology (SMT) is the backbone of modern electronics manufacturing. Precise placement, soldering, and inspection ensure that every component performs flawlessly under real-world conditions.

At inYantra, SMT assembly is executed using automated high-speed pick-and-place machines, reflow ovens, and AOI (Automated Optical Inspection) systems to ensure consistent accuracy and quality across every production batch.

Our SMT process ensures:

- Accurate component placement

- Consistent solder joint quality

- Minimal manual rework

- Stable long-term performance

2. Through-Hole and Mixed Technology Assembly

Many products today combine SMT and through-hole components – especially in automotive, industrial, and power electronics.

inYantra’s experienced team handles both technologies with precision, ensuring robust electrical and mechanical connections that can withstand vibration, heat, and long operational life.

3. Testing and Inspection: Reliability Built Into Every Stage

We integrate testing at multiple stages of production – not just at the end.

Each PCB goes through rigorous in-circuit testing (ICT), functional testing, and visual inspection to ensure it meets every specification.

Our quality checks include:

- Automated Optical Inspection (AOI)

- Functional and power-on testing

- X-ray inspection for BGA and hidden joints

- Environmental stress and reliability testing (as per customer need)

These steps help detect potential failures before the board leaves our facility – saving OEMs costly recalls or field failures.

4. Expertise in PCB Rework and Repair Services

Even with advanced automation, rework and repair capabilities are essential for quick turnaround and product optimization.

Our dedicated PCB rework station handles complex re-soldering, component replacement, and micro repairs – without compromising board integrity or performance.

This allows global OEMs to recover high-value assemblies and reduce material wastage, improving overall yield and sustainability.

5. Why PCB Assembly Quality Impacts Product Reliability

Poor soldering, component misalignment, or contamination can lead to:

- Early product failure

- Signal interference or heating issues

- Reduced lifespan and safety concerns

By ensuring precise SMT assembly, robust inspection, and complete process traceability, inYantra helps OEMs maintain product consistency, reduce warranty claims, and protect their brand reputation.

6. Partnering With inYantra for Reliable PCB Assembly

With decades of experience in PCB assembly in India, inYantra offers end-to-end build and assembly services – from sourcing to box build integration.

Our in-house teams ensure that each board is manufactured with attention to detail, meeting both RoHS and non-RoHS requirements.

Our key strengths include:

- High-speed SMT lines for precision

- In-house wiring harness and box-build capabilities

- Strong local supply chain for PCBs and components

- Proven expertise in automotive, medical, consumer, industrial, and IoT assemblies

Conclusion

Your product’s reliability begins with the PCB. Partnering with an experienced and certified manufacturer like inYantra Technologies ensures that your electronics are built to perform consistently and reliably.

Ready to enhance your product reliability?

Connect with our team to discuss your next PCB assembly or product integration project.